Rodrigo Escobar, Miembro del CEUC se adjudica Proyectos Fondecyt de Centros ANID

El Profesor del Departamento de Ingeniería Mecánica y Metalúrgica y Miembro del Centro de Energía UC, Rodrigo Escobar, fue uno de los 26 profesores que se adjudicaron Proyectos Fondecyt en la Escuela de Ingeniería.

A continuación, un abstract del Proyeto:

ABSTRACT:

|

Name of Responsible Researcher: |

Rodrigo Escobar |

|

Proposal Title: |

An evaluation methodology for green hydrogen production by high temperature electrolysis systems assisted by third-generation concentrated solar power plants |

Describe the main issues to be addressed: objectives, methodology and expected results. The maximum length for this section is 1 page (use letter size format, Verdana font size 10 or similar).

Currently, 80% of the global energy demand is covered by fossil fuels (FF); which are the main cause of climate change. Current geopolitical conflicts have shown that dependence on imported FFs leads to equity problems in energy access, impacting the economic growth of dependent countries. Efforts are oriented towards an energy transition to the use of non-conventional renewable energy (NCRE). However, NCREs by themselves cannot feed sectors such as heavy industry, maritime and air transport, since they require fuels that can be stored, transported and used in a comparable way to FFs. Under this paradigm, hydrogen (H2) stands as a potential energy substitute for FFs; since it offers a high gravimetric energy density of more than three times that of other fuels and a high potential for decarbonization and penetration in different productive sectors, such as the transport, electrical, agricultural, industrial and commercial sectors.

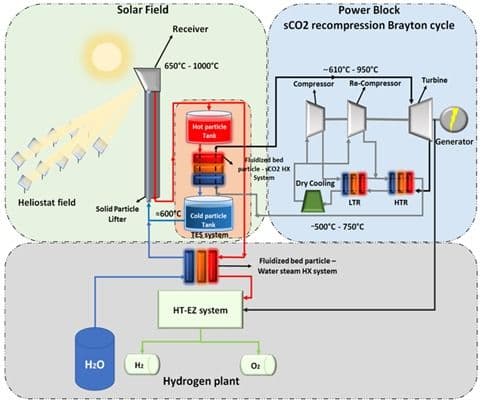

There are various processes for the production of H2 reported in the literature; however, water electrolysis (WE) processes stand out as the most appropriate options. Mainly, due to its high efficiencies, production costs, technological maturity and, since H2 production with zero emission can be ensured if the energy source that feeds the process comes from NCREs, currently known as green H2 (gH2). Alkaline Water Electrolysis (AWE) and Polymer Solid Membrane (PEM-WE) technologies are the most mature WE technologies on the market. These can be integrated with Concentrated Solar Power (CSP) and/or Photovoltaic (PV) technology, since they only require electricity for their operation; however, this coupling is not restrictive, so the WE plant may be in a different location than the solar power plant. High temperature electrolysis technology (HT–WE) or also known as steam electrolysis, requires both electricity and heat at high temperatures (between 600–1000°C), so it is imperative that the plant of HT–WE is located near a heat source. HT-WE technology has been shown to offer significant advantages over AWE and PEM-WE technologies, including higher electrolyzing efficiency (>90% over 700°C) and lower power consumption (approx. 35% lower). International experience has shown that the integration of HT–WE technology into processes where high-temperature waste heat can be used has great potential. To date, its evaluation has been restricted to coupling with conventional power plants, nuclear, second generation CSP (Gen2) and hybrid CSP Gen2 + PV schemes. However, these works present approaches that seek to maximize the annual production of H2 which is estimated through a global balance, ignoring operational, thermodynamic, and economic aspects, which can be optimized through a stationary or dynamic simulation over time.

The integration of HT–WE modules to a third generation (Gen3) CSP plant may be a promising scheme in terms of electrical power (EP) injection and gH2 production. Due to the operating ranges that both technologies share, they can be coupled to co-generate products with competitive costs compared to conventional technologies. However, there are significant challenges in determining its configuration, performance, and costs. A Gen3 + HT–WE CSP scheme has multiple design parameters: solar multiple (SM), storage hours, HT–WE plant size, among others, as well as parameters associated with the site (solar irradiation, ambient temperature and wind speed) and different modes of operation that complicate its analysis. Likewise, the economic analysis requires attributing the cost of the plant systems to the two products, H2 and electrical power, which are accounted for with different units. In addition, the plant presents periods of operation in partial load, due to the variability of the solar resource and the modes of operation, which increase the irreversibilities of the systems and decrease the efficiency of the plant. Therefore, the main objective of this research is to develop a methodology for the evaluation of HT-WE systems assisted by Gen3 CSP plants that allows the identification of inefficiencies during operation to improve the configuration, modes of operation and accounting for the flows of energy to perform an adequate attribution of the levelized cost of energy (LCOE) and H2 (LCOH2), considering hourly and sub-hourly temporal resolutions in order to define the appropriate temporal step to study the physical-chemical phenomena of the proposed scheme. Finally, to select the optimal configuration of the scheme studied, it is necessary to use a multi-objective optimization that determines the conditions of the place and the design parameters that maximize the energy and economic performance of the plant, to evaluate the performance of this scheme with CSP schemes of Gen3+PEM–WE and PV+BESS+PEM–WE as alternative solutions to supply gH2 and PE.

The proposed methodology contemplates three well-defined phases. In phase 1, a CSP plant will be modeled based on solid particle receivers, and then a PV, HT–WE and PEM–WE plant models will be developed, which will be integrated into Gen3+HT-WE, PV+BESS+PEM-WE and Gen3+PEM-WE CSP schemes. The modes of operation and dispatch of the schemes studied will be established based on different dispatch profiles. Phase 2 contemplates the performance of simulations and parametric analysis to analyze and understand the sensitivity of design parameters and their impact on performance indicators (KPI) such as LCOE, LCOH2, energy and exergetic efficiency of electrolysis, among others. In phase III, multi-objective optimizations will be carried out in order to find the integration schemes and plant sizes that allow these techno-economic performance indicators to be minimized and to analyze the effect of the degradability of HT- WE and PEM-WE on the LCOH2 of these schemes